How to

How to extend life of my Ariens snowblower?

Verify the mounting and shear bolts before every usage for tightness, your snowblower should be in safe working conditions at all times. You should also run the machine for few more minutes after snow removal process is complete to make sure that collector doesn’t freeze up

How to properly storage my Ariens snowblower?

Allow engine to cool down before you put it to storage. The tank should be emptied if your snowblower will be stored for more than 15 days. To transport your snowblower you need to move the attachment clutch to out position, move the speed selector to wanted speed and press down the handlebars and depress the clutch lever. Before long term storing perform was salt and all remaining debris from snowblower so that no corrosion occurs during the storage period, lubricate all necessary parts and touch up scratched surfaces

How to check dual handle interlock function?

Switch off the engine. Disengage two clutch levers and release the attachment. Remember to leave the cluth attachment engaged till you release the traction clutch lever. Both clutches should disengage the time, if they do not you will need to take your snowblower to a local service station

How to start my Ariens snowblower?

How to lubricate my snowblower?

Lubrication should be done every season or every 25 hours, whichever comes first. Ariens company advises to use Hi- Temp Grease in order to lubricate all fittings. Before lubrication wipe clean each fitting. Oil or grease shouldn’t get in touch with friction belt, disc or plate.

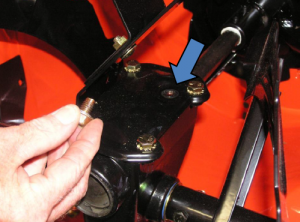

How to check the attachment brake?

In order to check the attachment brake you need to disengage the attachment clutch and make sure that the brake pad touches the attachment pulley. When attachment clutch is engaged pad shouldn’t be less than 12.7 mm it need to be replaced. Whenever in doubt replace in the service station

How to warm up my Ariens snowblower?

During period of very cold temperatures it is advised to let the engine warm up before it starts to throw the snow. In order to let it warm up switch on the machine and let it run for 1-2 minutes before you move the choke control to off position

What checks should be done on a daily basis?

Before each use following checks needs to be done: operation of clutch lever, dual handle interlock and engine oil. Also clutch cable attachment should be done every 5 working hours or so. Lubrication should be repeated every 25 hours or before each storage

How to adjust scraper blade?

Scraper blades should be adjusted regularly as when blades are worn they may cause auger housing damage. To adjust the scarper blade you simply need to tip back the unit into service position, then loosen buts that are keeping the blade, lower blades and tighten back the nut. Put the machine back to normal position and check if it operates normally

How to stop my snowblower?

In order to stop your snowblower you need to simply turn throttle down, then press rocket switch to stop position and remove the safety key. In emergencies you are allowed to remove the safety key or put press the rocket switch to stop position

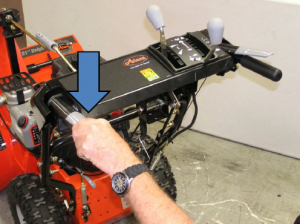

How to remove slack from attachment cable?

In order to remove slack from attachment cable you need to stop the engine wait for machine to cool down and all parts to stop. Once that is ready disconnect spark plug wire and loosen the cover belt and jam nut on the barrel of the cable. Turn the barrel down you will then shorten the cable and you will be able to remove the slack. After this tighten the jam but on the barrel and fix back the belt cover. Tighten all the nuts. Re-connect the spark plug wire

How to install discharge chute?

In order to install discharge chute you need to first grease the underside of the discharge ring chute. Once done remove the hardware from the auger housing, then install new chute over the auger housing opening. Tighten with the finger. If you want to replace the chute crank leave chute discharge pedestal loose if not tighten it

How to adjust discharge chute?

The discharge chute should be adjusted in all instances when it doesn’t stay in the selected position. In order to adjust discharge chute you should start from removing the discharge chute gear cover. Then you will need to loose the rear adjustment nut and the tighten till the lock arm engages the gear tooth. Once that is settled you can put and fix the discharge chute gear cover and verify that the machine works properly

How to check & adjust the tire pressure?

Tire pressure should be check on all tires, all tires should have the same pressure. Adjustments should be done till the amount specified on the tire sidewall. Never inflate tires above the recommended pressure and use only the hand pump. Never mount back a tire without having proper experience or tools.

How to install remote deflector control cable?

In order to install the remote deflector control cable you need to start from connecting the end of the barrel cable to the chute deflector cable anchor. Then clip the cable kin order to the discharge chute cable bracket. Put the deflector remote cable along the left side of the chute pedestal. On left side of chute deflector put in the barrel on the cable end into the bracket. Hold seal out of the way while routing the cable through the bracket on the left side of the discharge chute, and then push the cable fitting into the bracket. Seal the end on the cable fitting to prevent water from entering the cable. Verify the position of the deflector travel, adjust the cable nut if needed

How to check the clutch cable adjustments?

Impeller/ auger should stop within 5 seconds since the attachment clutch level release. Wheels should stop fast once releasing traction drive lever. If one or both of those don’t happen you need to make the adjustments.

How to check auger gearcase oil?

Place your machine on the level, flat surface. Remove seal washer and fill plug. Never remove the gearcase cover. Use a dipstick to check to oil level. If it is not 2.4-2.6 inch (6.1-6.7 cm) from the flat surface of the gearcase cover you need to refill it to required level. Do not overfill

How to adjust speed selector lever?

How to check belt finger clearance?

In order to check belt finger clearance you need to engage attachment clutch and verify that the belt finger- positioned on the other side of the belt idler needs to be lower than 1/8 inch or 3.2 mm. When the value is different you need to adjust the belt finger, it can be achieved by removing the belt cover, loosen bolts and move the belt finger to the proper position. Once done tighten the bolts and check that belt finger is now in correct position

How to adjust the traction drive clutch?

The traction drive clutch should be adjusted whenever snowblower is not driving correctly and to compensate for friction disc wear. In order to adjust the traction dive clutch you need to stop the engine, wait for all moving parts to stop and machine to cool down. Once that is ready you can disconnect the spark plug wire and loosen the but on the barrel of the traction cable, shorten the cable as needed and connect back the spark plug wire, and check the snowblower proper operation

How to adjust the drive disk?

The drive disk can be adjusted in order to compensate for friction wheel wear,which is easily observed by your machine slipping while the tractor clutch is engaged. You don’t need to remove the housing to make this adjustment. You just need to put the speed selector between reverse and first, tip and secure the machine, tighten the wheels adjustment nuts till wheals can hardly move